The job of a spray nozzle is simply to convert the spray solution into the right droplet formation for the spray target. It’s important to get this right so that you:

• don’t overdose, saturate the target and waste product,

• don’t spray droplets that are too large and that will simply bounce off the target,

• don’t spray droplets that are too fine and risk spray drifting onto non-target crops and plants,

• deliver too little solution that the process is completely ineffective.

If you add another product to your solution – for example, adding an adjuvant to a herbicide – it has the potential to change the quality of your spray, so it’s worth just bearing this in mind when selecting the right nozzle.

If you’re confident with nozzle differences, head straight over to our nozzle charts to make your selection.

Nozzle Basics

If you’re spraying a contact insecticide, herbicide or fungicide, you will need to ensure your nozzle allows for a fine droplet size. This is to make sure the solution is retained on the leaves.

If you’re spraying a systemic herbicide or fungicide, you will want medium droplets, and if you are spraying onto soil or using a residual product, you will want coarse droplets.

There are a range of nozzles available that will operate within these variables and ensure you get the best from the spray process. In summary, these are:

• Deflector

• Standard Flat Fan

• Low Drift Flat Fan

• Air Inclusion

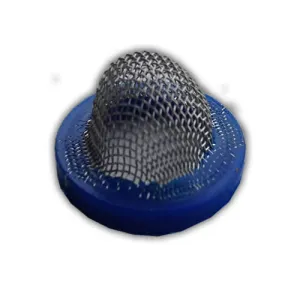

• Hollow Cone

• Full Cone

For the vast majority of garden projects, you are likely to use a fan or cone nozzle. All our nozzles are compatible with our Matabi, Cooper Peglar, and Berthoud sprayers.

Nozzle colours

Nozzles are helpfully colour-coded, based on the spray pattern. Each colour represents a different nozzle capacity – the differences influencing the final pressure and pattern of the spray, and therefore the droplet size.

The colours range from orange which has the lowest flow rate, to white which has the largest.

So how do you choose the right one for your job? Start by looking at the product label. Most products will dictate the ideal spray droplet size, so always check before starting any spray project.

Then consult our nozzle guide for detailed information. This guide shows the various nozzle choices based on speed, with guidance on the drop size for each.

Variables

Choosing the right nozzle depends on a few basic variables:

• The process you’re undertaking

• Walking or operating speed and technique

• The weather conditions

• The formulation of the product you’re spraying

• The equipment you’re using and the spray pressure

For insecticides, you will want a fine / small droplet size, so select a solid cone, hollow cone or flat fan nozzle.

For foliar spraying, you are likely to need a medium droplet size, so choose a deflector or flat fan nozzle.

In windy conditions, you will want a larger droplet size to prevent drift, so choose a deflector, and for residual herbicides, you will want a coarse or large droplet size, so choose a deflector.

The speed at which you walk / work can greatly influence the spray quality. Going too fast can increase the risk of spray drift. The height or distance from your spray target will also influence the spray quality.

Pressure also influences quality – as pressure increases, the droplet size will decrease, again increasing the risk of drift. A low operating pressure of 1 bar will produce larger droplets which are less prone to drift. Once you increase the pressure to 2 bar, the droplet size will decrease.

For manual spraying using handheld or knapsack sprayers, it is worth practising your spray technique with water before starting to spray and moderating your walking speed until you are satisfied with the spray quality.

For boom spraying, you will need to calculate the flow rate in order to select the correct nozzle. Contact our technical team if you have any questions about flow rate calculations. Our full nozzle guide can be found here.